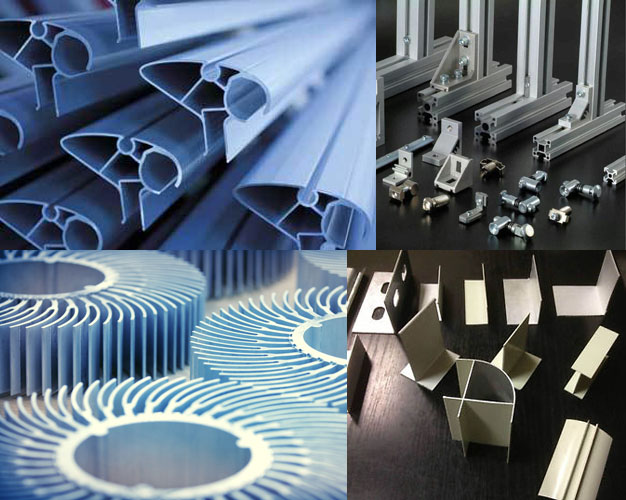

Aluminium extrusions offer designers a wide range of options in a variety of industries from aerospace, aviation, and car manufacture to mass produced consumer goods and panels for solar energy. The possibilities are endless. Architects favour the versatility of aluminium extrusions in creating buildings with innovative designs. Car manufacturers are discovering how lightweight components are able to replace steel for many parts.

Design Features

Aluminium extrusions are created when the metal has been heated sufficiently to be rammed through a die to form complex cross-sectional profiles for a variety of applications such as window frames. Aluminium extrusions are becoming the prime choice when designers are seeking to create innovative products for both small and large projects. Aluminium extrusions are lightweight and easy to machine, drill and saw. They are useful for single or batch components.

Special Properties

Aluminium extrusions are particularly corrosion proof with superior rust resistant properties making them ideal for designs that need to withstand the extremes of the weather. Other qualities which are seen as a positive advantage include the metal’s lightweight strength when compared to its much heavier steel counterpart.

Versatility And Temperature

Aluminium extrusions lend themselves perfectly to creating designs with curved sections. They can also be hollow increasing the lightweight functionality without depleting the structure’s strength. Objects such as furniture with tubular aluminium frames is just one example of how bent extrusions can be used in design. Aluminium becomes malleable at four hundred degrees Celsius which enables the extrusions to be formed into shapes, gaining in strength during the process. In cold temperatures, the aluminium gains even more strength and is a perfect solution to designing structures in particular circumstances such as in the aerospace industry.

Thermal Conductivity

Aluminium has a low density profile which makes it an ideal conductor of electricity with double the capacity of copper. Designers of overhead cable systems now use aluminium as their preferred choice. In smaller objects such as laptops and computers, aluminium extrusions are used for components that disperse heat effectively.

Cost Effective

Aluminium extrusions can be processed quickly helping designers get their products to market by the fastest route. Their versatility and potential for designs throughout any industry you care to think of is far reaching. The use of aluminium extrusions is extremely economic to work when compared to other metals. If your design requires aluminium extrusions Edmowill be able to offer cost effective solutions.